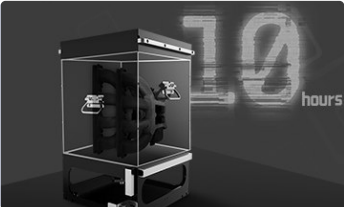

Industrial SLS 3D Printer

RP SLS2030

Details to see the truth

Ultra-high precision printing with wall thicknesses up to 0.6 mm Suitable for both test parts and practical applications

Focusing on 30 printers development and production

- Save material without removing excess material, improve material utilization, and reduce production costs by eliminating the need for production lines.

- High precision and complexity can be achieved, and very complex parts that cannot be made by conventional methods can be manufactured.

- 3D printing does not require a centralized fixed production plant and has the characteristics of distributed production.

- Automatically, quickly, directly and accurately converts 3D designs in computers into physical models, and can even directly manufacture parts or molds, thus effectively shortening product development cycles