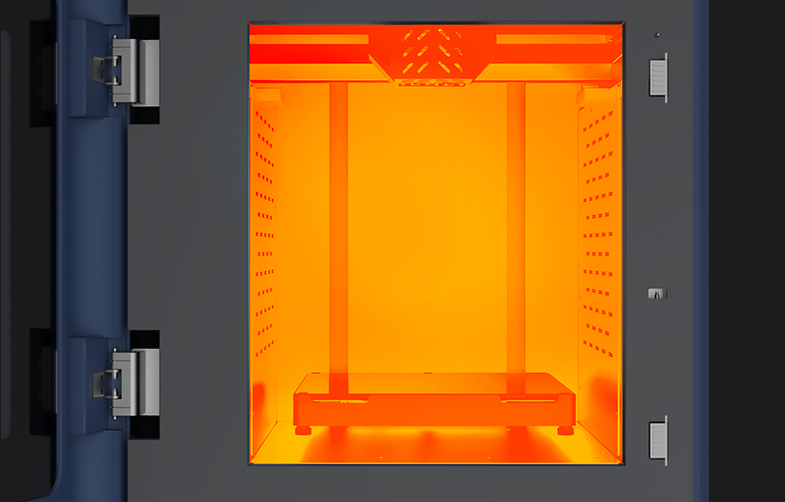

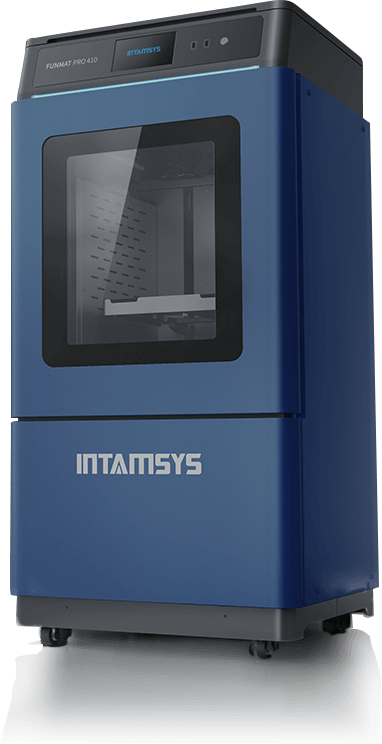

Advanced Thermal Design

Equipped with high-temperature, high-power dual-nozzle printing heads capable of reaching up to 500°C, a maximum printing chamber temperature of 90°C, and a maximum printing bed temperature of 160°C, the uniformly heated chamber ensures better mechanical properties.